|

| photo copyright Karin Corbin 2012 |

Cutting dormers for the Elizabethan birdhouse part 1

I still remember the days when I did not know how to approach making things like dormers for a miniature building. Lack of knowledge and often a lack of tools is where we all begin. This being a teaching blog I will show you how I am cutting the pieces for the front of a dormer that has a steep roof pitch. There are a number of methods to make these cuts and I don't always make them this way.

The miter angle fixtures that come with table saws won't rotate past 45 degrees but for this house I have to cut a sharper angle than 45. The method I chose is to make a single runner miter sled for my 10 inch table saw. I have a number of pieces to make using this particular angle so the jig will be useful for insuring all the parts get cut to that same exact angle without variation.

|

| photo copyright Karin Corbin 2012 |

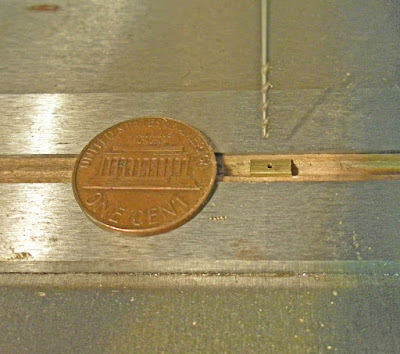

The runner that goes in the table slot could be made of hardwood or if it is only going to be used a few times pine or basswood will also do the trick. I am using a metal slide since I have one that I can unscrew and use it again and again for other jigs if I wish. As you will see I am using materials out of my scrap bin for the sled base and for the fence as well. Actually the plywood came out of a neighbor's scrap bin, I am not too proud to use his leftovers!

|

| photo copyright Karin Corbin 2012 |

As I am cutting this roof at a 60 degree angle I am using a drafting triangle with a matching angle to accurately establish the angle. I place the edge of the triangle right against the saw blade being sure it is not resting on any of the saw teeth, sneaking it between them, touching only on the flat of the saw blade. I have attached the fence to the base with double back carpet tape, it is plenty strong enough to hold it in place without shifting. I am using double back tape because I am going to reposition that fence to a couple of other angles for other dormers and gables and dormer roofs before I am done with all the cutting on this structure.

This first dormer front wall I am cutting has some vertical sides on it. Other dormers and gables I will cut are simply triangles with no vertical sides on them. I am showing those in other postings.

|

| photo copyright Karin Corbin 2012 |

First the dormer plywood material is cut to width. Then I mark out how tall the vertical sides are. I make sure the mark at the point where the roof pitch starts gets transferred on down the edge of the plywood. That mark is going to be aligned with the cut edge of my miter jig. See photo above, it will enlarge if you click on it. This is a quick, simple and accurate method of aligning the starting point of the cut for the sloped roof line on the dormer.

|

| photo copyright Karin Corbin 2012 |

The first cut goes just past the point of the peak.

|

| photo copyright Karin Corbin 2012 |

Then the board is flipped, aligned to the mark and the second cut is made.

|

| photo copyright Karin Corbin 2012 |

Notice how my board is left longer than the length of the small dormer, it gives me good registration against the fence. I will cut the second dormer piece I need from the other end of the board. That butterfly shaped piece left in the middle will still be there for a nice long registration against the fence.

That center waste piece has complimentary angles that will soon be recycled into making yet another miter sled jig for cutting the timber frame trim pieces that will go onto this dormer and on the gable ends of the house. Be sure to watch for opportunities like this because they give you those exact matches on angle cuts that will fit perfectly onto your house parts. I will show you the jig I make from it later on in this blog.

If I was making a dormer with equal side lengths I could have used a stop block on the fence for the second cut. But these dormers are on each side of another third dormer that sits between them and the peak is not centered across the width of the dormer. You can see the dormers I just cut on the CAD model in the image below. They are on the left and right of the center dormer. Elizabethan birdhouse image below.

|

| photo and design copyright Karin Corbin 2012 |

Link to Cutting Dormers: Part 2

Link to Cutting dormers: Part 3