|

| photo copyright Karin Corbin 2009 |

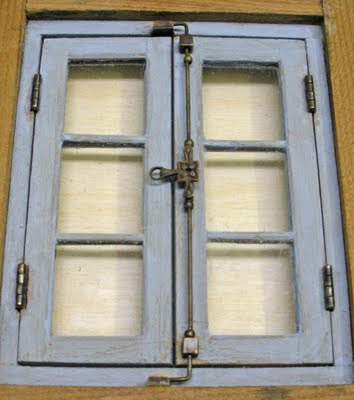

My lighting for the box bed seems to be good enough that I can go ahead and put a roof on it. I can see into the box bed from a dark dollhouse interior; it won't be overly bright once there are lights in the rest of the dollhouse and there are still shadows inside the box bed.

|

| photo copyright Karin Corbin 2009 |

There is enough light to see the carved baby bed looking into the little window in the box bed.

|

| photo copyright Karin Corbin 2009 |

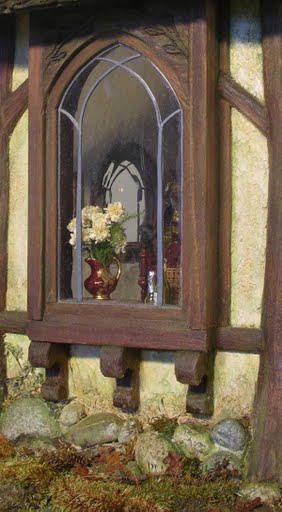

I can also see the carved baby bed from the outside the dollhouse looking through big window on the front of the dollhouse.

|

| photo copyright Karin Corbin 2009 |

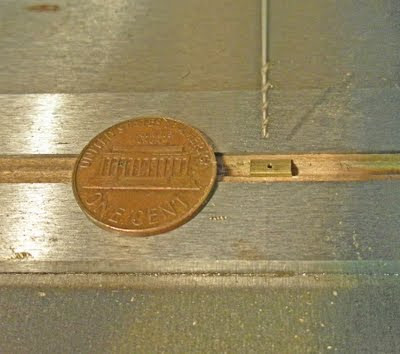

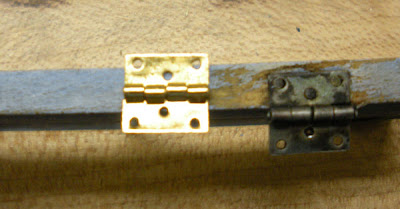

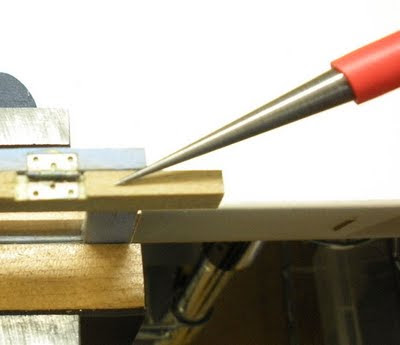

For my test I took one wire from each of the lights, twisted the bare ends of wires to form a pair of wires. That made two pairs, you could call one a positive pair and the other negative if that terminology makes more sense to you. I then put one of the pairs under the screw on a small terminal block and then the other pair went on the strip next to it. The other side of the terminal strip has a wire under it that comes from a 12 volt transformer. If you look closely at the terminal block you will see that there is a divider in the middle that prevents the negative and positive pairs from coming into contact with each other. If they contacted it would create a short circuit and blow the fuse in the transformer. As long as you keep your pairings from getting mixed up you will find that dollhouse wiring is very straight forward and very easy to do. One wire from a light bulb goes to one bundle, the other wire from the light goes into a different bundle. You can color code those wires coming off the light bulb, just make one of them black with a felt tip marker if you like. If you enlarge the photo you will see where I have used a black marker on the ends of one of the pairs.

So wherever you make joins all the wires in one bundle would be black, all the wires in the other bundle would be white. They must never make bare wire contact between white bundle and black bundle. Color coding will make visible and simple to understand what is happening and very easy to avoid mistakes. Just remember you never want both wires coming from a light bulb ending up in the same bundle on its way to the transformer. If you can keep that very simple rule straight in your head then you can successfully wire a dollhouse and get everything to light up. White to white, black to black, never mix them up in the same bundle.