I started testing stucco last night. The store has changed brands on me. The stucco material I used to buy is no longer there. Last night I did a test patch of the new product they are carrying. I like it better in many ways, it is lighter in weight, the size of the bits of sand is smaller, it does spread nicely, it is not as sticky.

Some things I don't like better, it is too white, it is not as sticky, there are areas on the structure where I want to have larger grit showing. Ah you see there is no pleasing me, I want it sticky but not sticky and big grit as well as small grit. In order to get the right look for an old stucco wall that has cracking and failing plaster I have to use multiple products applied in layers. That is because that is how the real houses are created. I can also modify a product with bigger grit and a change of color and then layer on those variations. That may be what I will do this time around.

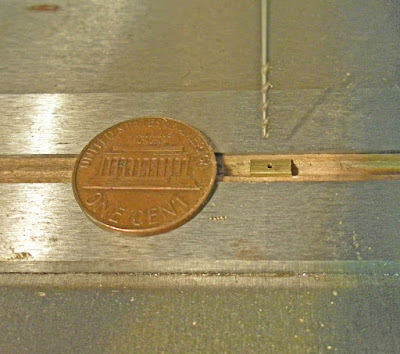

My goal will be to create a stucco that is showing age, has cracks and loss of plaster but is not completely decrepit. I am not building a haunted house, I am building a normal house that is in need of some attention. The photo below is a good reference for how that looks on a real structure. I will be having a few areas where the plaster is coming off in larger sections, that is not shown in the photo.

The real life stucco process on a timber framed house starts with a very course mix of clay, straw, sand and other inclusions. That thick stuff is pushed into the underlying structure of wattle. Wattle is basically little sticks sprung or woven in the openings. Then what modern plaster masters would call the scratch coat is applied, that layer also has grit or other inclusions in it but it is not a course. After that comes a coat of smooth plaster. The last coating is a lime wash. The lime wash is to plaster walls what paint is to wood walls. It provides a protective coating that helps resist water.

Timber frame houses are an interesting architectural structure in terms of engineering. They move and they breathe. Moisture from inside the house can pass out through the plaster walls, that helps prevent issues such as toxic mold and rotting wood. The frames stay in good condition because of the plaster. When the plaster fails you dig it out and fill it back in again. There is a constant cycle of stress on the plaster, wind rain and movement due to changes in humidity. Only a newly plastered house would have the completely smooth texture from using a product such as Creative Paperclay or lightweight spackling compound or plaster. Only a newly plastered house would be free of cracks, stains and dirt. I don't build newly plastered houses so to achieve realism I use a combination of products of different textures and colors applied in layers.

Because I will also be applying paints, glaze and washes to the surface I need to have my stucco materials be water resistant. A wash of dirty looking water will melt and smooth away sharp edges of broken plaster if I make it from lightweight hole filling product unless I choose to use an exterior product that dries to a water resistant surface. There is also the issue of the color of materials. The course daub (torchis) is not the same color as the white lime wash or colored lime wash. In some geographic areas of the world the earth the minerals used to make the layers of materials that make up the infill will be off white, other areas have a golden tint or it could be grey and even reddish brown. Different layers such as the filler will be a color that does not match the final lime wash. What the local land provided is what you got. They did not run to the local giant warehouse home improvement store as I can. They will very likely have mixed their own stucco products for the various layers from basic materials using the locally favored formula passed around by word of mouth.

Set a time and a location for your project and then support your decisions with research. Remember to use materials the characters who inhabited your story house would used. They had to shop locally if they lived in the previous centuries unless they were very wealthy.

Quick and easy methods for dollhouse building are great but only if they make a believable finished product. Not all dollhouses have to be believable but sometimes that is the goal. Other times they are much like a stage or movie set, the designer edits out details and emphasizes others to create an artistic impression on the viewer. Either way take the time to think it all out decided on a direction and then

be consistent and faithful to that course

.

The photos below are some that I took on my tour of Normandy. Some show failing stucco and one shows newly restored stucco.